Low Volume Production

Leveraging the Low volume production excellence

Even with mass production dominating the modern manufacturing arena, low volume production has still found substantial traction across industries seeking to strike a balance between scalability and individualization. They cater to specialized and limited demand, providing a unique balance between quality, customization, and efficiency.

Low volume production and low volume manufacturing are emerging in demand concepts that address the intricacies of specialized production and foster the creation of tailored, high-quality goods. In this article, we will delve into the basics of these concepts and explore their significance in today’s rapidly evolving market.

Why use low volume batch production?

Low volume production refers to the process of crafting limited quantities of a product to exact specifications. Unlike the high-speed assembly lines of mass production, it embraces a deliberate pace, allowing for unparalleled attention to detail and precision. Low volume manufacturing, on the other hand, dovetails seamlessly into the world of customized creation. While production often connotes an industrial churn, manufacturing is an art that brings together engineering ingenuity and craftsmanship. Here, the objective shifts from sheer volume to producing limited runs of products that are distinguished by their exclusivity.

Some of the qualities that make low volume production gain momentum include:

Meeting Niche Demand:

· The creation of a limited number of units of a product allows low volume production to be tailored for products that have niche markets, specialized requirements, or are in the early stages of development.

Efficiency:

· By focusing on optimizing the manufacturing process for small quantities, low volume production carefully analyzes each step of the manufacturing process, from raw material sourcing to assembly. In addition, low volume manufacturing aims to minimize waste, reduce setup times, and streamline operations.

Balanced quality and customization:

· The ability to swiftly adapt to market demands is crucial and enables manufacturers to offer tailored solutions while avoiding the excessive costs and potential waste associated with large-scale operations without compromising on product qualities.

Sunray Precision Prototype is a reliable rapid prototyping service company that offers low volume production solutions alongside other precision prototypes, vacuum casting, CNC machining, and other services.

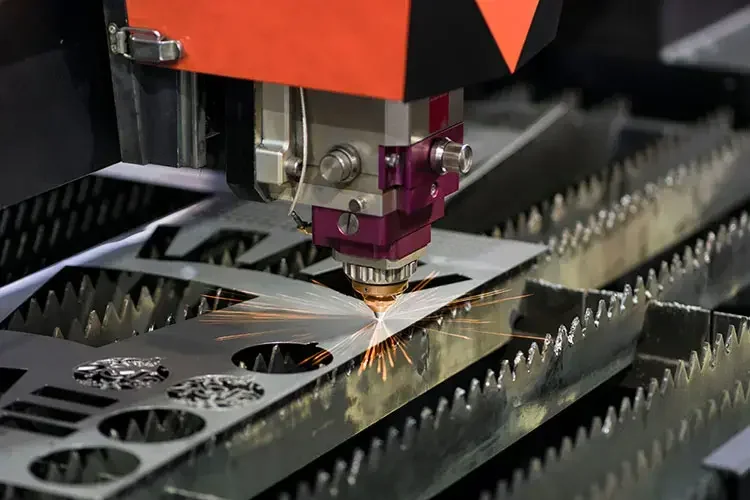

We combine low volume manufacturing with in-house advanced digital technologies, automation, and skilled craftsmen to avoid the risks and costs associated with scaling too quickly to mass production and benefit from:

· Save costs; reduce risks;

· Shorten the time to market, thus gaining more market shares and revenue;

· Enhance design flexibility: modify the design without compromising the total orders;

· Produce parts as needed without worrying about the MOQ;

· Help small start-up companies introduce their innovations and test their products on the market.

Sunray Precision Prototype works to provide a balanced approach to manufacturing in a rapidly changing world and foster quality, customization, and efficiency to cater to the needs of niche markets and empower innovation through low volume production. Contact us for more information or inquiries.

CNC Machining

A subtractive manufacturing solution produces wide range of precision metal and plastic end-users parts and prototypes

Vacuum Casting

Produce high quality end-users parts withoutbuilding expensive hard tooling

3D Printing

Additive manufacturing produces plastic andplastic-like parts, products with complexgeometries and surface detail.

Contact Us